Comparative Analysis of Tunnel Oxide Deposition Techniques in Topcon Solar Cells

Solar Cells Nano-scaled SiOx Layer, Topcon Solar Cells, Tunnel Oxide Deposition

Tunnel Oxide Deposition Techniques for Nano-scaled SiOx Layer in Topcon Solar Cells

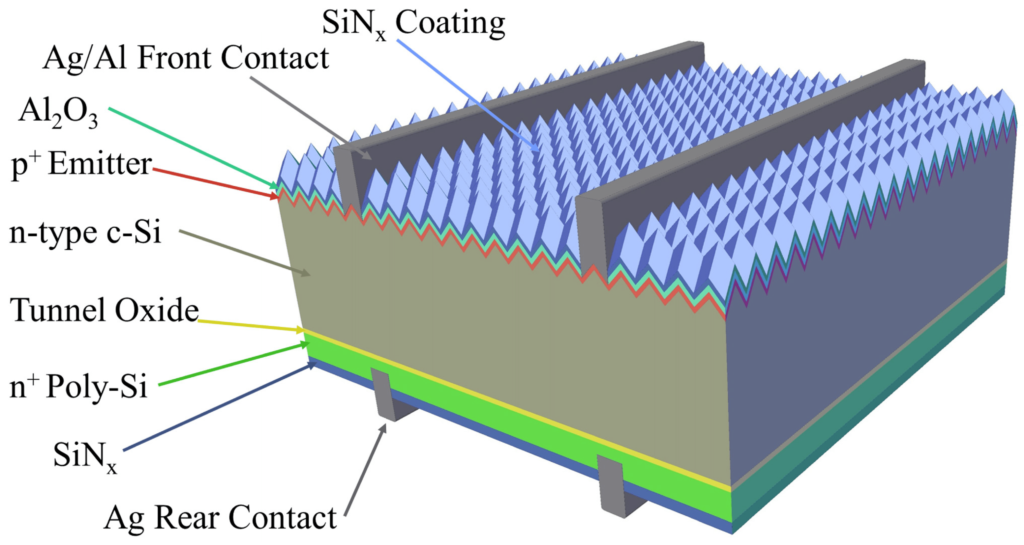

Topcon solar cells have gained significant attention in recent years due to their high efficiency and potential for cost-effective production. One crucial component of these solar cells is the nano-scaled SiOx layer, which acts as a tunnel oxide. The deposition techniques used for this layer play a vital role in determining the overall performance of the solar cell. In this review, we will explore different tunnel oxide deposition techniques and their parametric influence on the nano-scaled SiOx layer in topcon solar cells.

1. Thermal Oxidation

Thermal oxidation is one of the most commonly used techniques for depositing the tunnel oxide layer in topcon solar cells. In this process, a silicon wafer is exposed to high temperatures in an oxygen-rich environment. The oxygen molecules react with the silicon surface, forming a thin layer of SiOx. The thickness of the SiOx layer can be controlled by adjusting the temperature and duration of the oxidation process.

The parametric influence of thermal oxidation on the nano-scaled SiOx layer is significant. Higher temperatures and longer oxidation times result in thicker SiOx layers, which can affect the electrical properties of the tunnel oxide. It is crucial to optimize the oxidation parameters to achieve the desired thickness and quality of the SiOx layer.

2. Plasma Enhanced Chemical Vapor Deposition (PECVD)

PECVD is another widely used technique for depositing the tunnel oxide layer in topcon solar cells. In this process, a plasma of reactive gases is used to deposit a thin film of SiOx on the silicon wafer. The reactive gases, such as silane and oxygen, are excited by the plasma, leading to the formation of SiOx.

PECVD offers several advantages over thermal oxidation, including better control over the deposition process and the ability to deposit uniform and conformal films on complex surfaces. The parametric influence of PECVD on the nano-scaled SiOx layer includes the gas flow rates, plasma power, and deposition temperature. Optimizing these parameters is crucial to achieve a high-quality SiOx layer with the desired electrical properties.

3. Atomic Layer Deposition (ALD)

ALD is a precise and controllable technique for depositing thin films, including the tunnel oxide layer in topcon solar cells. In ALD, the deposition process occurs in a cyclic manner, with alternating exposures to precursor gases. Each cycle results in the deposition of a single atomic layer, allowing for precise control over the film thickness.

The parametric influence of ALD on the nano-scaled SiOx layer is significant. The choice of precursor gases, deposition temperature, and cycle times can affect the film’s composition, density, and electrical properties. ALD offers excellent uniformity and conformality, making it an attractive option for depositing high-quality tunnel oxide layers in topcon solar cells.

Conclusion

The choice of tunnel oxide deposition technique plays a crucial role in determining the performance of the nano-scaled SiOx layer in topcon solar cells. Thermal oxidation, PECVD, and ALD are three commonly used techniques, each with its parametric influence on the electrical properties of the tunnel oxide. Optimizing these parameters is essential to achieve a high-quality SiOx layer with the desired thickness and electrical characteristics. Further research and development in tunnel oxide deposition techniques will continue to enhance the efficiency and reliability of topcon solar cells.